More Links:

Official show notes:

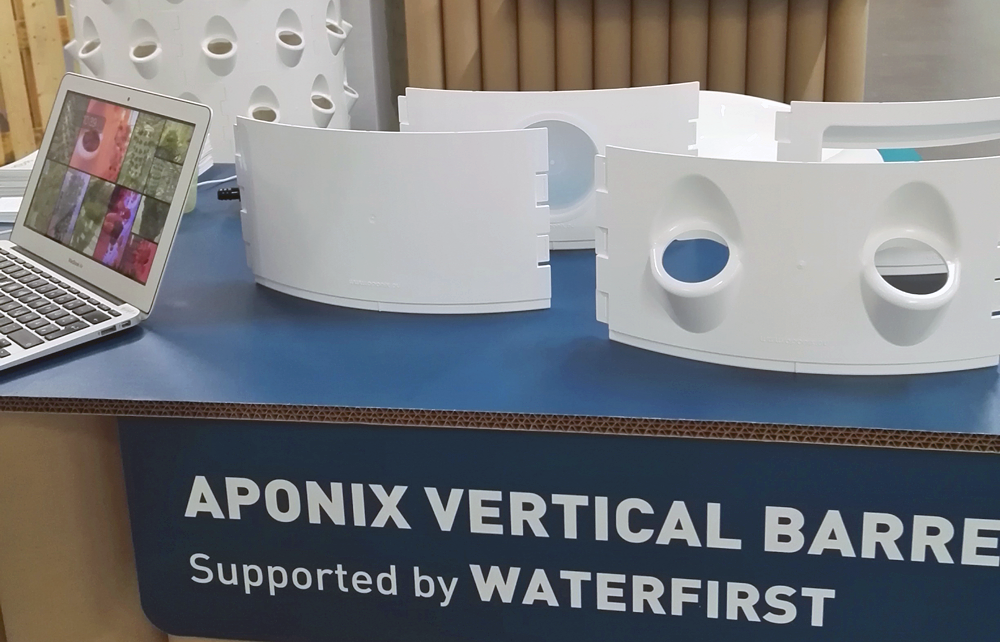

EN: The aponix vertical barrel enables you to set up vertical grow spaces in a very flexible and modular way. By chosing from a range of different parts you can assemble ring segments and stack the into a vertical cylinder or barrel (diameter 57 centimeters). The cultivation area is the surface of the cylinder and it can provide differently sized grow spaces for your crops. Irrigation is done at one entry point from the top either by using a standard inverted sprinkler, an aeroponic spray nozzle or our own irrigation buffer that can be operated by a simple pump. You can use it as a single barrel with the base being the reservoir or arrange multiple barrels in a production line using a central nutrient reservoir. The system works just the same as a normal NFT but in 3D. For exmaple setups and images please visit our website www.aponix.eu.

DE: Die vertikale Pflanztonne von aponix ermöglicht es, einfach schnell und flexibel vertikale Pflanzplätze aufzubauen. Es werden keine fest eingebaute Teile wie Tische bei NFTs oder Regale benötigt. Durch die Auswahl und den Zusammenbau von Ringsegmenten eines vertikalen Zylinders (Durchmesser 57cm), können ‘Tonnen’ aufgebaut werden, die an deren Oberfläche Pflanzplätze bieten. Die Oberfläche kann je nach Auswahl der Bauteile für unterschiedliche Pflanzgrößen konfiguriert werden. Durch Aufstapeln von Ringsegmenten, schafft man sich eine ‘Tonne’ variabler Höhe. Bewässerung erfolgt von oben mittels Sprinkler, Aeroponik-Düse oder eines eigenen Bewässerungspuffers, der mit einer einfachen Pumpe befüllt werden kann. Der Betrieb kann als Einzeltonne erfolgen. In diesem Fall ist der Ständer das Reservoir. Es können auch mehrere Tonnen in Reihe mit einem zentralen externen Reservoir erfolgen. Funktionsweise is prinzipiell wie mit einem NFT, allerdings in 3D. Für Beispiele besuchen Sie bitte unsere Website unter www.aponix.eu.

Aponix had its first appearance at

Aponix had its first appearance at

At this year’s green tech in Amsterdam aponix had the corner booth again in the AVF pavilion and also participated in the

At this year’s green tech in Amsterdam aponix had the corner booth again in the AVF pavilion and also participated in the