Summary: Co-creative urban farming and vertical farming offer innovative ways to grow food in urban areas, promoting sustainability, social equity, economic development, and community building. These approaches can help to increase access to fresh, healthy, and locally-grown produce, reduce the environmental impact of traditional agriculture, create new job opportunities, and build community engagement and social connections. While there are bottlenecks to implementing these activities, such as land availability, cost, regulations, technical expertise, and community engagement, working together to overcome these challenges can create more sustainable, locally-based food systems in urban areas.

—

Marco: Can you explain co-creative urban farming and more technical vertical farming to me?

ChatGPT: Co-creative urban farming is an approach to farming in which community members, farmers, and other stakeholders work together to plan, design, and maintain urban farming projects. This approach emphasizes collaboration and participation, with a focus on creating sustainable, locally-based food systems that are accessible to all. Co-creative urban farming often involves using vacant lots, rooftops, and other unused urban spaces to grow food, and can incorporate a variety of farming techniques, such as container gardening, raised beds, and aquaponics.

Vertical farming, on the other hand, is a type of indoor farming that involves growing crops in vertically-stacked layers or towers, often using artificial lighting and hydroponic or aeroponic growing systems. This approach to farming can be highly efficient, allowing for year-round crop production in a controlled environment that minimizes water use and eliminates the need for pesticides and herbicides. Vertical farms can be located in urban areas, allowing for fresh produce to be grown and distributed locally, reducing the environmental impact of transportation and supporting local food systems.

Both co-creative urban farming and vertical farming offer innovative approaches to sustainable agriculture, and can help address issues such as food insecurity, environmental degradation, and climate change.

–

Marco: Any other synergies or benefits for citizens and the region?

ChatGPT: Yes, there are several synergies and benefits that can arise from co-creative urban farming and vertical farming for citizens and the region:

Improved food security: Co-creative urban farming and vertical farming can help to increase access to fresh, healthy, and locally-grown produce, especially in food deserts and low-income areas where access to fresh produce is limited.

Environmental sustainability: Both approaches can reduce the environmental impact of traditional agriculture, such as reducing water usage, eliminating the need for pesticides and herbicides, and reducing transportation emissions by producing food locally.

Economic development: Co-creative urban farming and vertical farming can create new job opportunities in the region, from farm labor to marketing and distribution. It can also support the growth of local businesses, such as restaurants and grocery stores that feature locally-grown produce.

Community building: Co-creative urban farming can help to build community engagement and social connections, bringing together diverse groups of people to work towards a common goal. Vertical farming can also engage community members through education and outreach programs.

Innovation and education: Both co-creative urban farming and vertical farming can offer opportunities for innovation and education, such as developing new growing techniques or experimenting with new crop varieties. This can also help to promote STEM education and engage young people in agriculture and environmental sustainability.

Overall, co-creative urban farming and vertical farming can offer a range of benefits to citizens and the region, promoting environmental sustainability, social equity, economic development, and community building.

Marco: Yes, if the local administration would check their inventory of available and usable spaces, they would probably create a lot of farmers without own land by just taking care for a friendly and attractive environment for them and their work. This should also include public, semi-public and private spaces that could be identified and then classified and potentially included into the system. All these empty spaces hold a lot of potential for aspiring urban farmers, as they can be used to grow healthy and nutritious food for their communities and at the same time provide decent work with a purpose. After a while this would also transform those areas significantly.

–

Marco: What kind of horticulture equipment would you say is key in promoting creativity for urban gardening setups and collaboration?

ChatGPT: There are several types of horticulture equipment that can be key in promoting creativity and collaboration for urban gardening setups:

Raised garden beds: Raised garden beds can be constructed in a variety of shapes and sizes, making them a flexible and customizable option for urban gardening. They can be used to create visually interesting designs and can be placed on any surface, including concrete or asphalt.

Vertical gardening systems: Vertical gardening systems, such as living walls, trellises, and hanging baskets, can be used to add visual interest to urban gardening spaces, and can be used to grow a variety of plants, including vegetables, herbs, and flowers.

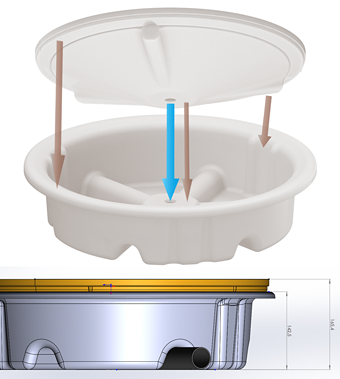

Hydroponic systems: Hydroponic systems can be used to grow plants without soil, using a nutrient-rich water solution instead. These systems can be used to grow plants indoors or outdoors and can be customized to fit the needs of specific plants.

Irrigation systems: Irrigation systems, such as drip irrigation or sprinkler systems, can be used to water plants efficiently and effectively. These systems can be customized to fit the needs of specific plants and can be set up to water plants automatically, freeing up time for gardeners to focus on other tasks.

Composting systems: Composting systems, such as worm bins or compost tumblers, can be used to create nutrient-rich soil amendments from organic waste. These systems can be used to reduce waste and improve soil quality in urban gardening spaces.

By providing access to these types of horticulture equipment, urban gardening setups can promote creativity and collaboration among community members, allowing for a wide range of plants to be grown and encouraging community members to work together towards a common goal.

–

Marco: What would you say could be the bottlenecks in having more such activities in urban areas?

ChatGPT: While co-creative urban farming and vertical farming can offer a range of benefits, there are also several bottlenecks that can make it challenging to implement such activities in urban areas:

Land availability and access: One of the biggest bottlenecks is the availability and access to land in urban areas. Finding suitable land for urban farming can be difficult, and often requires working with city officials, property owners, and community groups to identify and secure suitable locations.

Cost: Co-creative urban farming and vertical farming can require significant upfront costs for equipment, infrastructure, and labor. These costs can be a barrier to entry for some individuals or organizations, particularly those with limited financial resources.

Regulations and zoning: Urban farming can be subject to a range of regulations and zoning restrictions, which can limit the types of activities that can take place and the locations where they can occur. Working with local officials and policymakers to develop supportive regulations and zoning codes can help to overcome these bottlenecks.

Technical expertise: Co-creative urban farming and vertical farming require specialized knowledge and technical expertise in areas such as horticulture, hydroponics, and urban design. Access to training and technical assistance can help to build the capacity of individuals and organizations to implement these activities effectively.

Community engagement: Co-creative urban farming and vertical farming require strong community engagement and support to be successful. This can require significant outreach and education efforts to build awareness and generate interest among community members.

Overall, addressing these bottlenecks requires a coordinated effort involving multiple stakeholders, including city officials, community groups, nonprofits, and private sector organizations. By working together to overcome these challenges, it is possible to create more sustainable, locally-based food systems in urban areas.

–

Marco: People might ask with which urban farming products they should start their gardening journey. Can you make a list of the most exciting ones and give pricing indications?

ChatGPT: Certainly, here are some of the most exciting urban farming products that can be used for starting a gardening journey, along with pricing indications:

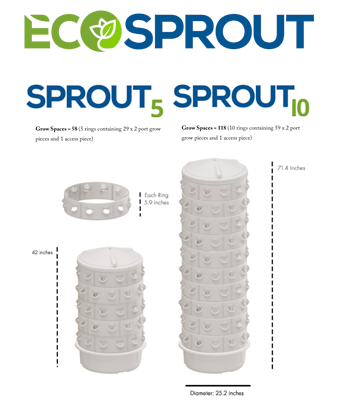

Vertical hydroponic systems: Vertical hydroponic systems allow for plants to be grown without soil, using a nutrient-rich water solution instead. These systems can be customized to fit the needs of specific plants, and can be used indoors or outdoors. Prices can range from $50 for smaller systems to several thousand dollars for larger commercial systems.

Self-watering planters: Self-watering planters are a low-maintenance option for growing plants in urban spaces. These planters contain a water reservoir that provides plants with the moisture they need, reducing the need for frequent watering. Prices can range from $20 for smaller planters to several hundred dollars for larger options.

Raised garden beds: Raised garden beds are a flexible and customizable option for urban gardening, and can be constructed in a variety of shapes and sizes. These beds can be used to grow a range of plants, including vegetables, herbs, and flowers. Prices can range from $50 for smaller beds to several hundred dollars for larger options.

Composting systems: Composting systems can be used to create nutrient-rich soil amendments from organic waste, reducing waste and improving soil quality in urban gardening spaces. Options include worm bins, compost tumblers, and bokashi bins, with prices ranging from $30 to $300.

Greenhouses: Greenhouses allow for year-round growing in urban areas, protecting plants from harsh weather conditions and extending the growing season. Greenhouses can be constructed in a range of sizes and styles, with prices ranging from a few hundred dollars for smaller, portable options to several thousand dollars for larger, permanent structures.

These are just a few of the many options available for starting an urban farming or gardening journey. Prices can vary depending on factors such as size, material, and features, but there are options available to fit a range of budgets and needs.

–

Marco: How about walls, micorgreens and young plants?

ChatGPT: Walls, microgreens, and young plants are also exciting urban farming products that can be used to start a gardening journey. Here are some examples and pricing indications:

Living walls: Living walls are a vertical gardening option that can be used to grow a range of plants in a small space. These walls can be customized to fit a variety of settings, including indoor and outdoor spaces. Prices can vary depending on the size and complexity of the living wall, with smaller, more basic systems starting at around $100.

Microgreens: Microgreens are young plants that are harvested when they are only a few inches tall, and are often used as a garnish or ingredient in salads, sandwiches, and other dishes. Microgreens can be grown indoors or outdoors, and can be grown in soil or hydroponic systems. Prices for microgreens seeds and growing equipment can vary depending on the type of system used, but can range from $20 to $100.

Young plants: Young plants, such as seedlings and transplants, can be a great way to start an urban garden without the need for extensive equipment or infrastructure. These plants can be purchased from local nurseries or online, and can be used to grow a range of vegetables, herbs, and flowers. Prices for young plants can vary depending on the species and size, but typically range from a few dollars per plant to several dollars for larger transplants.

Overall, walls, microgreens, and young plants are all exciting options for starting an urban farming or gardening journey, and can be tailored to fit a variety of budgets and needs.

–

Marco: Would you say our planet would be a better place if we had more urban farming initiatives?

ChatGPT: Yes, I believe that our planet would be a better place if we had more urban farming initiatives. Urban farming has the potential to bring a range of social, environmental, and economic benefits to communities, including:

Improved food security: Urban farming can help to increase access to fresh, healthy, and locally grown produce, reducing the reliance on imported or processed foods and improving food security for urban populations.

Reduced environmental impact: Urban farming can help to reduce the carbon footprint of food production and distribution, as locally grown produce requires less transportation and packaging, and can reduce the need for chemical fertilizers and pesticides.

Increased community engagement: Urban farming can provide opportunities for community members to connect with each other and with the natural world, fostering a sense of community and promoting social cohesion.

Economic development: Urban farming can create jobs and support local economies, particularly in areas with high unemployment or underutilized land.

Overall, urban farming can be a powerful tool for promoting sustainability, resilience, and community well-being, and can contribute to a healthier, more equitable, and more sustainable future for our planet.

–

Marco: Thank you! You would be a good gardening buddy to have on the urban farming heros team!

ChatGPT: Thank you, I’m always here to help with any questions you may have! Happy gardening!

—

So I added the

So I added the

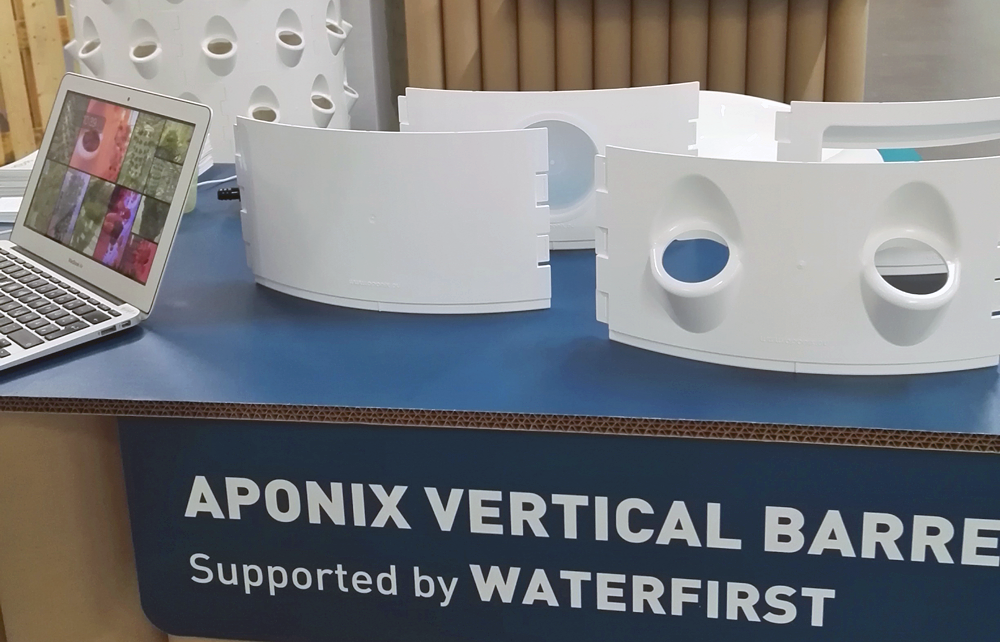

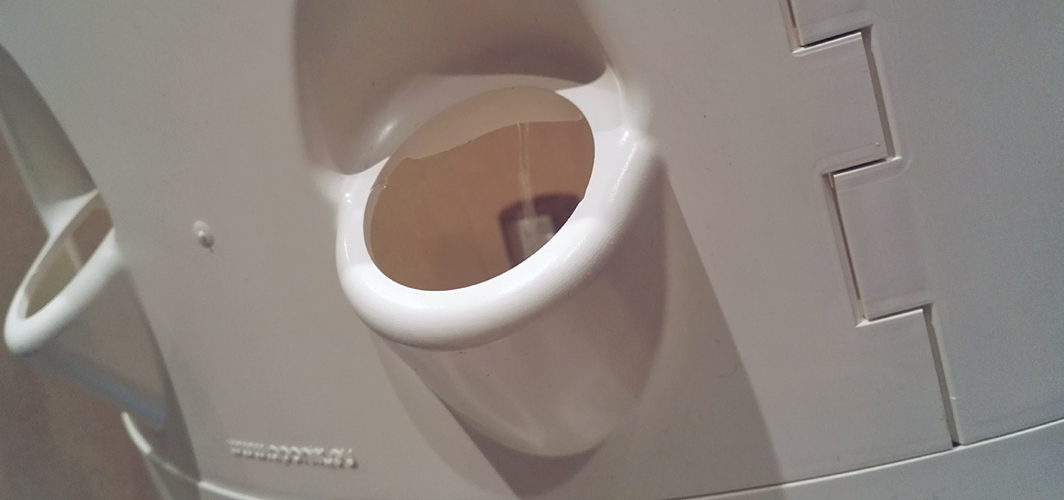

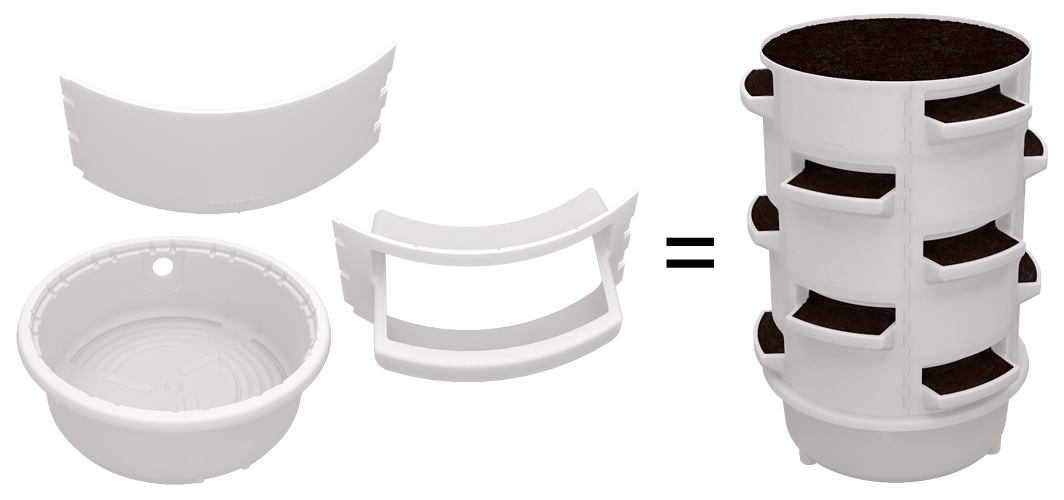

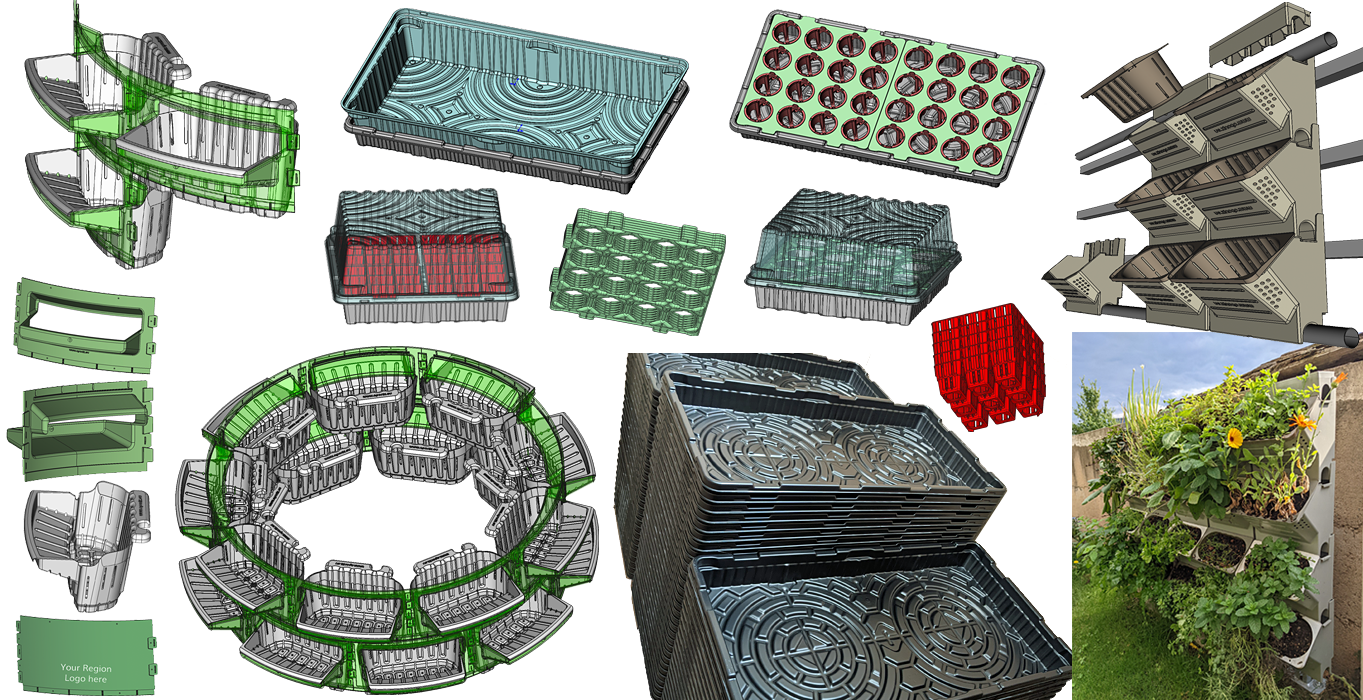

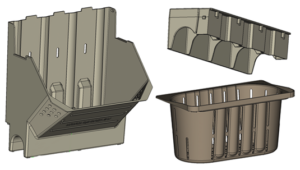

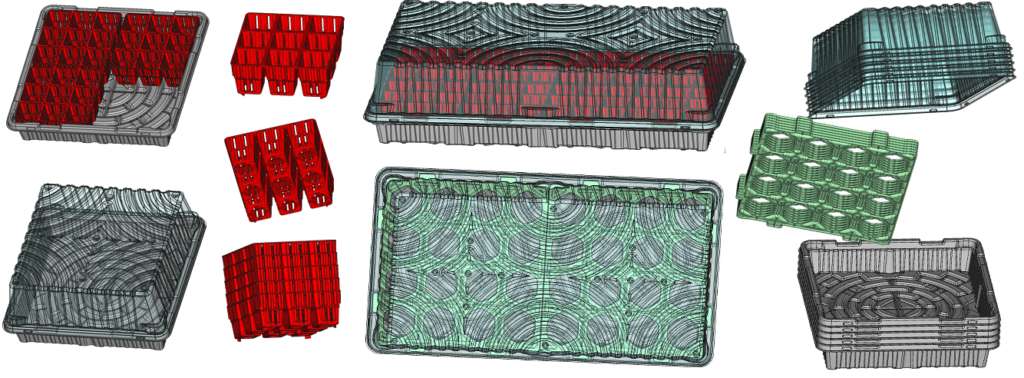

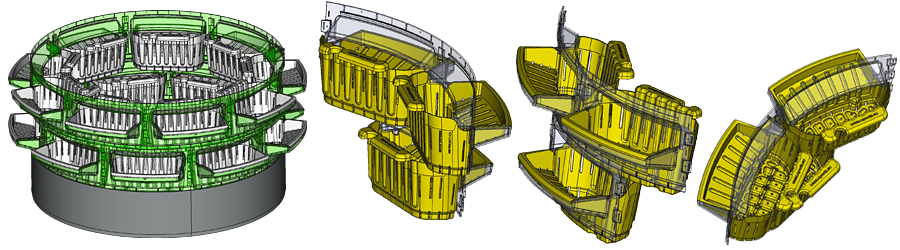

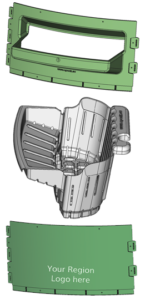

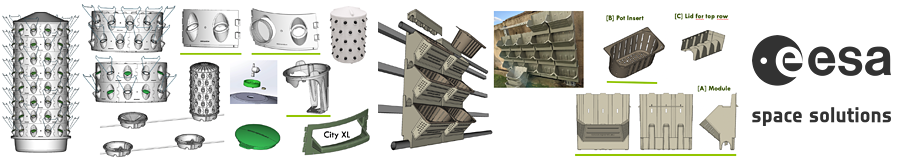

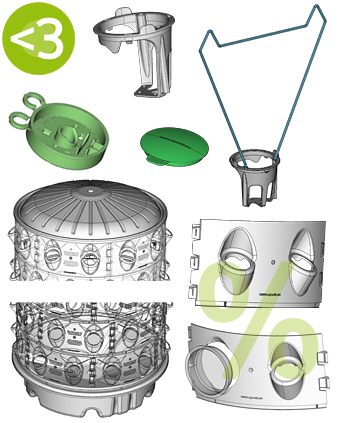

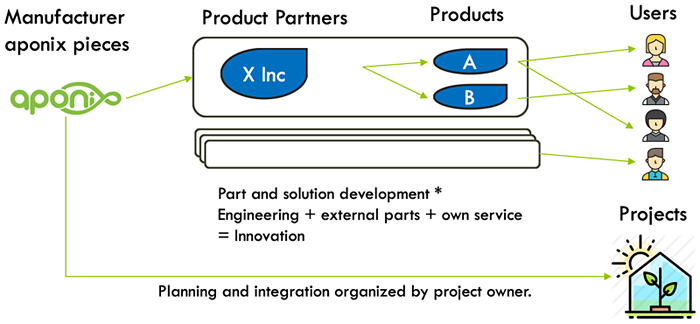

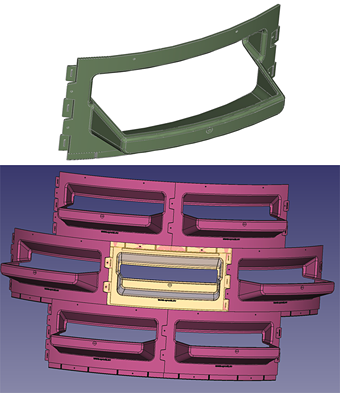

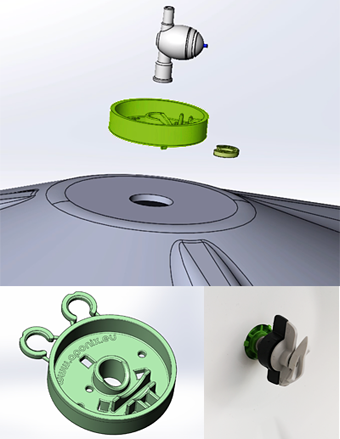

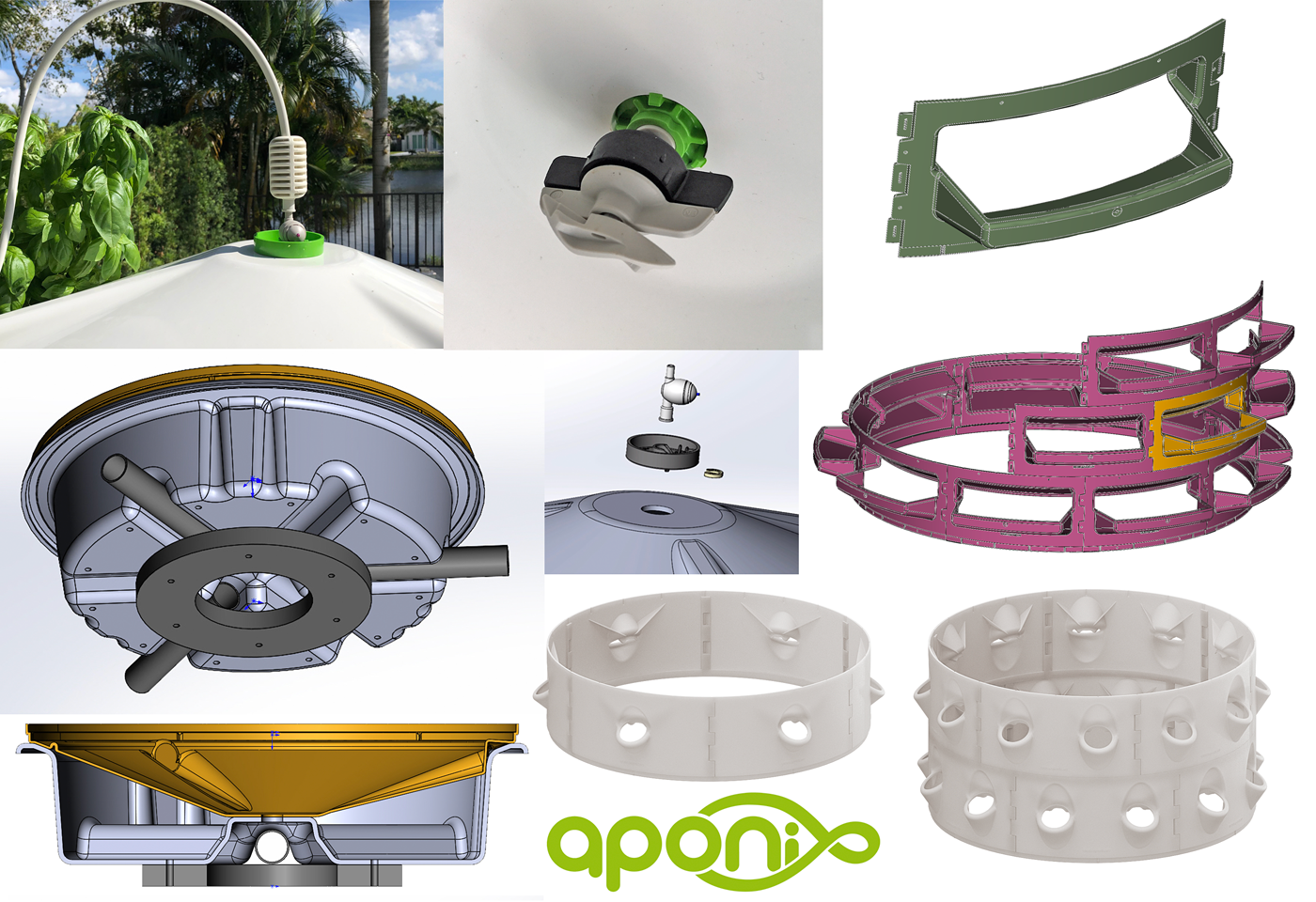

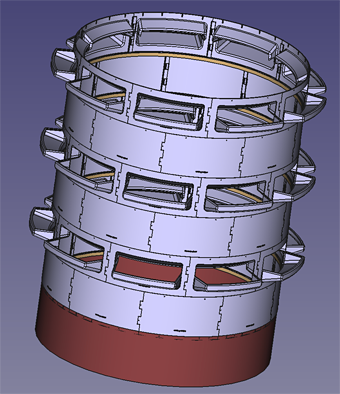

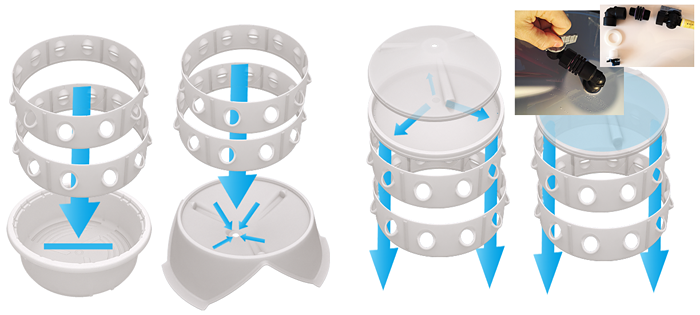

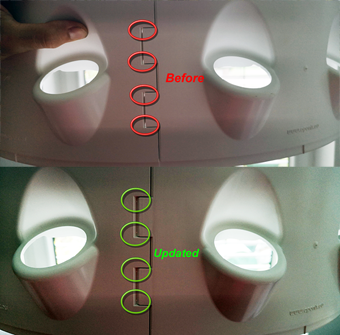

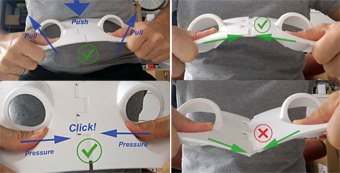

Apart from collecting new ideas for solutions, coming up with potential designs, validating them and finally bringing them into large series production, my second most important focus became inspiring urban farmers by showing them the variability and modularity of my designs and the creative ways other users use these solutions even finding completely new use cases. I think part of it is the right timing but also the insights that people get from discussing their potential and possible applications and solutions freely in a playful and inspirational way. I am convinced that the real innovation is created in these brainstorming sessions with pragmatic users. Aponix just provides some solid modular infrastructure components for them.

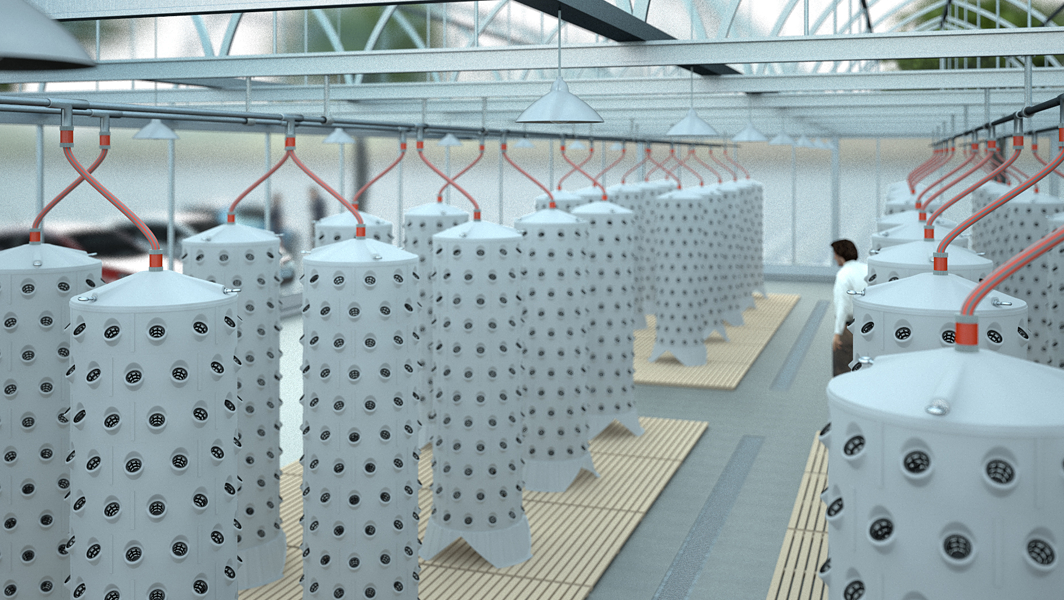

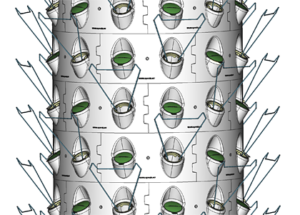

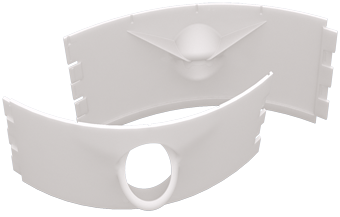

Apart from collecting new ideas for solutions, coming up with potential designs, validating them and finally bringing them into large series production, my second most important focus became inspiring urban farmers by showing them the variability and modularity of my designs and the creative ways other users use these solutions even finding completely new use cases. I think part of it is the right timing but also the insights that people get from discussing their potential and possible applications and solutions freely in a playful and inspirational way. I am convinced that the real innovation is created in these brainstorming sessions with pragmatic users. Aponix just provides some solid modular infrastructure components for them. Most of the technology needed to grow more plants in the urban and peri-urban areas is already existing and usually used by commercial growers. Once we learn to combine proven methods, equipment with the awareness that more vegetation and hyperlocal edible plants are able to solve a multitude of planetary and social issues, my hope is that users will come up with new ways and formats naturally. This is where the concept of the component based urban farming equipment of aponix tries to be a catalyst: Once interested users are given modular equipment that can be implemented into the urban context well and policy makers and communities give room and incentivize participatory projects, we will see a multitude of creative innovation.

Most of the technology needed to grow more plants in the urban and peri-urban areas is already existing and usually used by commercial growers. Once we learn to combine proven methods, equipment with the awareness that more vegetation and hyperlocal edible plants are able to solve a multitude of planetary and social issues, my hope is that users will come up with new ways and formats naturally. This is where the concept of the component based urban farming equipment of aponix tries to be a catalyst: Once interested users are given modular equipment that can be implemented into the urban context well and policy makers and communities give room and incentivize participatory projects, we will see a multitude of creative innovation.

Thanks to some close relationships into Dutch horticulture and good friends from there who support our product development with expertise, contacts and insights, we started to finally go this path collecting the missing ideas for standards in lighting, ventilation, processes, added robustness etc. From the beginning the aponix components were meant to be usable in commercial and also larger professional setups.

Thanks to some close relationships into Dutch horticulture and good friends from there who support our product development with expertise, contacts and insights, we started to finally go this path collecting the missing ideas for standards in lighting, ventilation, processes, added robustness etc. From the beginning the aponix components were meant to be usable in commercial and also larger professional setups.

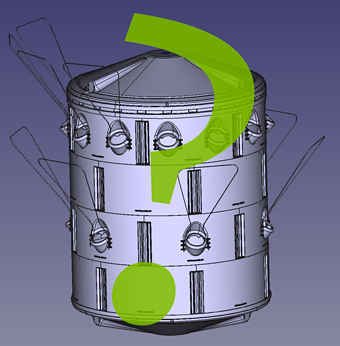

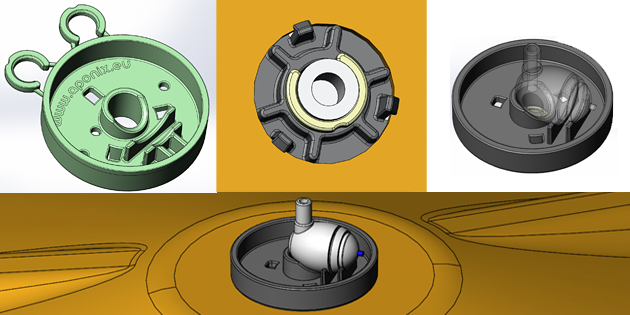

Another product based on the vertical barrel concept has been co-created – a

Another product based on the vertical barrel concept has been co-created – a

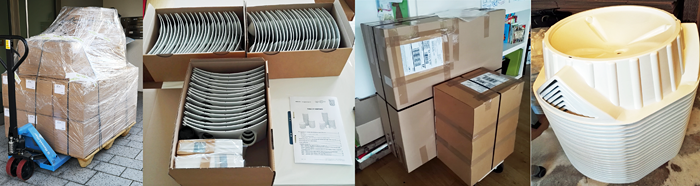

7. Test package 7 ring segments

7. Test package 7 ring segments 8. Help! Google reviews!

8. Help! Google reviews! 9. Value adding resellers wanted

9. Value adding resellers wanted

Aponix had its first appearance at

Aponix had its first appearance at

At this year’s green tech in Amsterdam aponix had the corner booth again in the AVF pavilion and also participated in the

At this year’s green tech in Amsterdam aponix had the corner booth again in the AVF pavilion and also participated in the