[Link to the original newsletter]

- Version 3 vertical barrel components available now! Foreword from the inventor Marco.

- Offer to all existing V2 users.

- Components overview and function description.

- Focus on the new V3 ring segment piece. What is different now?

- New product: Living WallSystem coming April/May 2021.

- Shout-out to our existing users please add comments share production images.

- Looking for partners to share part of their booth with aponix as co-exhibitor.

- US product partner EcoSprout with standalone setup and consumables.

- What is an aponix vertical barrel?

1.Version 3 vertical barrel components available now!

Foreword from the inventor Marco

We are honored and proud to offer our extended and improved 3rd generation of the initial design idea of a lego based modular and versatile set of components to set up 3D soilless grow spaces that make it possible to use natural sunlight in small and medium sized farming setups: aponix vertical barrel, now Version 3 ready for your order.

We are honored and proud to offer our extended and improved 3rd generation of the initial design idea of a lego based modular and versatile set of components to set up 3D soilless grow spaces that make it possible to use natural sunlight in small and medium sized farming setups: aponix vertical barrel, now Version 3 ready for your order.

In this newsletter we like to show the different components in more detail and update you on the design changes we made in the central Version 3 ring segment piece. This part will probably be most interesting for the existing Version 2 users who already followed us on our journey and in turn made Version 3 possible. We have a special reward for our longterm supporters later in this newsletter.

From the last years of observing the larger ‘PFAL setups’ (Plant Factory using Artificial Light) we learnt that using multi layer rack based indoor setups, restricts these installations to crop classes like micro greens, baby leaf lettuce and leafy greens unless we attach them directly to a clean and very cheap energy source clearly below 0.10EUR/kWh. Don’t get me wrong, we will need those farms and they are spectacular and technically awesome, no question. But they still have some way to go and evolve. There are many more applications and use cases especially in urban farming that need to be integrated into the wider smart city context and your daily urban life that also add focus to social and educational aspects. Our core mission at aponix is and stays to provide easy to use, robust and very modular infrastructure components to empower urban entrepreneurs to do exactly that.

To give you one more interesting perspective: Whereas the focus of PFAL ambitions seem to automate production and remove human labor from the value creation, we intentionally want to create a pleasant space of purposeful work spaces as part of a sustainable urban life with our products and use natural sunlight as much as possible. In that tradition we have just extended our vertical barrel to be able to grow also fruiting crops inserting an optional metal plant trellis into grow spaces and switch crops as needed. We also designed a new modular living WallSystem that will be available from April/May 2021 (for more details see below) that makes unused walls also farmable or just beautifully contributing to urban microclimate, storm water retention adding more jungle to your life and urban biodiversity.

To give you one more interesting perspective: Whereas the focus of PFAL ambitions seem to automate production and remove human labor from the value creation, we intentionally want to create a pleasant space of purposeful work spaces as part of a sustainable urban life with our products and use natural sunlight as much as possible. In that tradition we have just extended our vertical barrel to be able to grow also fruiting crops inserting an optional metal plant trellis into grow spaces and switch crops as needed. We also designed a new modular living WallSystem that will be available from April/May 2021 (for more details see below) that makes unused walls also farmable or just beautifully contributing to urban microclimate, storm water retention adding more jungle to your life and urban biodiversity.

I would like to encourage and invite all prosumers, consumers, educators and citizens to become an active part of this much more integrated way of living and like to remain with my promise to inspire, empower and encourage everyone I see and meet in that same direction.

Stay strong ^^

Stay healthy ^^

Yours,

Marco

2. Offer to all existing V2 users.

We decided to offer a 30% discount (regular net price 5.20EUR) on the new Version 3 ring segment pieces to all users who supported us in the past by purchasing and using Version 2 in case they like to upgrade.

All large components are perfectly backwards compatible. You could even stack complete V2 ring segments with V3 ring segments. We also added some backwards compatible new components that you could integrate into existing setups even without upgrading:

Grow Space Cover, reusable Plug Pot with optional metal trellis, Sprinkler Dome with any sprayer or our Netafim adapter integrating Netafim 4/7mm tubing and nozzles, Lid-Base. Shipping just ring segment pieces without the large parts is also very compact, since you can and should continue to use all your existing larger components.

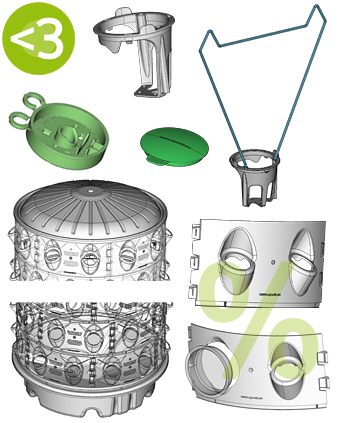

3. Components overview and function description.

The first step to understand the modularity is to learn about the different options to take configuration decisions for A) the entry of the liquid nutrients on the top, and B) what to do with the liquid when it reaches the bottom of a unit.

Between Version 2 and Version 3 we kept the major metrics like diameter, grow space size, stacking mechanism so all existing large parts are still usable. You could even stack fully assembled V2 and V3 ring segments in a mixed barrel. The material stays the same: ASA with highest UV resistance, food safe and still valuable raw materials after its end of life.

To get a quick component and arrangement intro, please check our 4 page 3D-NFT info sheet.

At the center there will only be one V3 ring segment piece: See section 4. for a full list of all the changes. This will make production and logistics much simpler compared to the different types in V2.

At the center there will only be one V3 ring segment piece: See section 4. for a full list of all the changes. This will make production and logistics much simpler compared to the different types in V2. The V3 revision piece is just the regular piece with one grow space sacrificed to a larger capped opening to reach inside during operations. So in V3 you have 1 remaining and usable grow space in your revision pieces.

The V3 revision piece is just the regular piece with one grow space sacrificed to a larger capped opening to reach inside during operations. So in V3 you have 1 remaining and usable grow space in your revision pieces. Unused grow space cover: Instead of using ring segment pieces with different grow space configurations, we decided to offer a nice green grow space cover. In larger setups you can use it to adjust for high or lower grow space density according to the size and shape of your crop. In hobby setups, where there are usually unused grow spaces it can be used as a flexible means to close these openings.

Unused grow space cover: Instead of using ring segment pieces with different grow space configurations, we decided to offer a nice green grow space cover. In larger setups you can use it to adjust for high or lower grow space density according to the size and shape of your crop. In hobby setups, where there are usually unused grow spaces it can be used as a flexible means to close these openings. Aponix Plug Pot and metal trellis ‘Fox’: We wanted to integrate an optional metal plant trellis insert to support larger crops and fruit with flexible trellis shapes. Engineering around this feature request we discovered that it would be much more useful to do a separate young plant holder or ‘Plug Pot’ to provide an alternative to the single use standard netpots. The aponix Plug Pot has an exact diameter of 5cm and can also be used in other systems. Of course it works best in our vertical barrels. We also provide one shape of a galvanized metal trellis (same like a tomato hook), model ‘Fox’. But you could use or bend your own. The metal needs to have a 3mm diameter.

Aponix Plug Pot and metal trellis ‘Fox’: We wanted to integrate an optional metal plant trellis insert to support larger crops and fruit with flexible trellis shapes. Engineering around this feature request we discovered that it would be much more useful to do a separate young plant holder or ‘Plug Pot’ to provide an alternative to the single use standard netpots. The aponix Plug Pot has an exact diameter of 5cm and can also be used in other systems. Of course it works best in our vertical barrels. We also provide one shape of a galvanized metal trellis (same like a tomato hook), model ‘Fox’. But you could use or bend your own. The metal needs to have a 3mm diameter. Sprinkler dome: Our normal lid never really worked well with any sprinkler. In order to enable reliable sprinkler usage we designed a dedicated sprinkler dome that you can use with any sprinkler mounted on top that suits your desired flow rate. We still can provide the small inverted Senninger sprinkler. But you could also attach any other one with a flow rate <=2l/min.

Sprinkler dome: Our normal lid never really worked well with any sprinkler. In order to enable reliable sprinkler usage we designed a dedicated sprinkler dome that you can use with any sprinkler mounted on top that suits your desired flow rate. We still can provide the small inverted Senninger sprinkler. But you could also attach any other one with a flow rate <=2l/min. Netafim adapter: We like the concept of adapters to use other existing and proven components. In this case we built against the egg-like Netafim drip stop component you might know from overhead seeding irrigation in greenhouses. It clicks tightly onto our sprinkler dome lid and can be attached and run with the existing Netafim irrigation equipment including a bunch of different spray nozzles.

Netafim adapter: We like the concept of adapters to use other existing and proven components. In this case we built against the egg-like Netafim drip stop component you might know from overhead seeding irrigation in greenhouses. It clicks tightly onto our sprinkler dome lid and can be attached and run with the existing Netafim irrigation equipment including a bunch of different spray nozzles. Waterbuffer: In order to go with low pressure in your circulation and much simpler pumps mostly in smaller hobby or solar powered setups you will need to put a waterbuffer on top of your barrel(s). This will be covered with our normal lid. For standalone units where we use a closed base as reservoir we drill a center hole to attach an internal hose for liquid circulation. Without this hole you irrigate from the top through the center of the lid.

Waterbuffer: In order to go with low pressure in your circulation and much simpler pumps mostly in smaller hobby or solar powered setups you will need to put a waterbuffer on top of your barrel(s). This will be covered with our normal lid. For standalone units where we use a closed base as reservoir we drill a center hole to attach an internal hose for liquid circulation. Without this hole you irrigate from the top through the center of the lid. Lid: Still the old lid to cover the waterbuffer. It can also be used as base for a hanging setup adding stainless steel ring hooks at the end of the 3 ridges or it is used as insert into the new lid-base.

Lid: Still the old lid to cover the waterbuffer. It can also be used as base for a hanging setup adding stainless steel ring hooks at the end of the 3 ridges or it is used as insert into the new lid-base. Lid-base + Lid: This new base was the result of a co-operation with a product partner, who needed a way to make units rotate. The lid base is much smaller than the old and much bigger (discontinued) multi barrel base and provides space underneath for a standard 40mm PVC draining pipe that is put into position just by placing the lid-base on top. You always need to insert an upside-down lid so your liquid drains to your drain piping from its center.

Lid-base + Lid: This new base was the result of a co-operation with a product partner, who needed a way to make units rotate. The lid base is much smaller than the old and much bigger (discontinued) multi barrel base and provides space underneath for a standard 40mm PVC draining pipe that is put into position just by placing the lid-base on top. You always need to insert an upside-down lid so your liquid drains to your drain piping from its center. Closed Base: This is still used for standalone setups as reservoir or as spacious base to set up the substrate version, which will keep the Version 2 connections.

Closed Base: This is still used for standalone setups as reservoir or as spacious base to set up the substrate version, which will keep the Version 2 connections.

4. Focus on the new V3 ring segment piece. What is different now.

Many changes taking more control and improve what is happening inside the vertical barrel.

Many users were reporting frequent leaks using V2 between the ring segment click connections and the grow spaces. So we completely reinvented the connection mechanism with everything we learnt in the meantime about adhesion and cohesion in the behavior of liquid and by literally observing liquid flow patterns inside for many hours. The click connection design is now based on a hexagon. This closes much more tightly with more overlap closing out light completely now and made the ends more robust. 2 users actually managed to break off one of the teeth in V2. So this change was important to us.

Many users were reporting frequent leaks using V2 between the ring segment click connections and the grow spaces. So we completely reinvented the connection mechanism with everything we learnt in the meantime about adhesion and cohesion in the behavior of liquid and by literally observing liquid flow patterns inside for many hours. The click connection design is now based on a hexagon. This closes much more tightly with more overlap closing out light completely now and made the ends more robust. 2 users actually managed to break off one of the teeth in V2. So this change was important to us. We are also taking much more control over liquid flow and liquid distribution on the inside now to prevent any potential permanent liquid film from forming on connecting elements during irrigation. This was the main cause for frequent V2 leaks (sorry in retrospect for this). Additionally the new inside wing structure provides much more stability stacking higher units without becoming less compact to ship and store.

We are also taking much more control over liquid flow and liquid distribution on the inside now to prevent any potential permanent liquid film from forming on connecting elements during irrigation. This was the main cause for frequent V2 leaks (sorry in retrospect for this). Additionally the new inside wing structure provides much more stability stacking higher units without becoming less compact to ship and store. The above design changes tightened up the connectors to the maximum and reduce the leaks by ~80%. Since we are working with humid air inside the units during irrigation cycles we wanted to provide an additional way for users who wanted to make the units completely liquid tight. The new hexagonal shape provides 2 areas with surfaces where users can apply a liquid sealant if they really need it. See this Facebook Usergroup post. Basically when assembling your ring segments you place a pea sized spot of food grade silicone/sealant in these two spots and then connect the pieces. This forms a flexible seal that will wash away when you disassemble the pieces any time later. In order to provide this function, the upgrade to the hexagon was also critical.

The above design changes tightened up the connectors to the maximum and reduce the leaks by ~80%. Since we are working with humid air inside the units during irrigation cycles we wanted to provide an additional way for users who wanted to make the units completely liquid tight. The new hexagonal shape provides 2 areas with surfaces where users can apply a liquid sealant if they really need it. See this Facebook Usergroup post. Basically when assembling your ring segments you place a pea sized spot of food grade silicone/sealant in these two spots and then connect the pieces. This forms a flexible seal that will wash away when you disassemble the pieces any time later. In order to provide this function, the upgrade to the hexagon was also critical.- In V2 we had 3 different pieces: Completely closed, one center net pot and our the most popular piece with two netpots. This made production and part logistics complicated. In V3 there is only one piece with two net pot inserts. Unused grow spaces can be capped with our new green grow space cover or any other practical home made option. The revision piece is also based on this part with a sacrificed grow space but one remaining grow space.

Many users stacked the V2 ring segments differently because there were 4 stacking options but most of the times only one of them was ideal. With V3 there are only 2 stacking positions that make a clear difference in the vertical positioning of the grow spaces. Two other small but effective improvements for stacking are: We switched the positions of the dent and the tooth so the bottom of a ring segment can always be inserted into a perfectly circular base. This could also be a custom base of a more integrated use case for our vertical barrels. This was actually an idea from one of our product partners. And we added an additional support in the center of the pieces to make high units more stable.

Many users stacked the V2 ring segments differently because there were 4 stacking options but most of the times only one of them was ideal. With V3 there are only 2 stacking positions that make a clear difference in the vertical positioning of the grow spaces. Two other small but effective improvements for stacking are: We switched the positions of the dent and the tooth so the bottom of a ring segment can always be inserted into a perfectly circular base. This could also be a custom base of a more integrated use case for our vertical barrels. This was actually an idea from one of our product partners. And we added an additional support in the center of the pieces to make high units more stable. The material choice for the more UV resistant and more durable ASA instead of any other like the usual ABS was confirmed by the users. This material also has the nice property that in its pure form, it can be 100% cycled cradle to cradle style to make new pieces after the end of their life with exact the same material properties like new ones; making it a real cradle to cradle technical cycle product. That is why we looked into an official c2c certification but soon discovered it is very expensive and time consuming to later just use a logo. So we engraved this reminder to the backside of every V3 ring segment piece: “This material is valuable quality ASA, optimized to become raw material again by upcycling. Sort and reintroduce into the technical cycle after end of life. Never dispose to landfill or trash, even prevent downcycling.”

The material choice for the more UV resistant and more durable ASA instead of any other like the usual ABS was confirmed by the users. This material also has the nice property that in its pure form, it can be 100% cycled cradle to cradle style to make new pieces after the end of their life with exact the same material properties like new ones; making it a real cradle to cradle technical cycle product. That is why we looked into an official c2c certification but soon discovered it is very expensive and time consuming to later just use a logo. So we engraved this reminder to the backside of every V3 ring segment piece: “This material is valuable quality ASA, optimized to become raw material again by upcycling. Sort and reintroduce into the technical cycle after end of life. Never dispose to landfill or trash, even prevent downcycling.” We also changed the shape of the backside behind the grow space insert to force liquid to fall to the next level. In V2 when liquid was coming down at a certain angle it could adhere to the inside of the grow space insert, crawl up and end up on the outside of a unit.

We also changed the shape of the backside behind the grow space insert to force liquid to fall to the next level. In V2 when liquid was coming down at a certain angle it could adhere to the inside of the grow space insert, crawl up and end up on the outside of a unit.

5. New product: Living WallSystem coming April/May 2021.

As initially with the vertical barrel in 2015, it seemed to us like there are already many wall systems out there but most of them use felt/fabric that look awesome freshly installed but become often problematic over time. Some crucial functions for maintenance and growing different types of also edible plants and variabilities for use in very different conditions and for different substrate types could not be found – especially not within the same system as options. So we did it again… we just designed our ideal component for the job.

Difference to other living wall systems:

- Only 3 pieces. Anything else needed are standard building components like 32mm PVC pipe and drip emitters for irrigation from the top row and drainage – standards horticulturists already know and use.

- No fabric/felt.

- Module based, organized in rows and columns, 25 modules cover 1sqm.

- Very competitively priced.

- Water retention with adjustable water level per module and even complete delayed draining possible.

- Removable/replaceable pot insert (22x11cm opening) with air pot root design shape and air insulation for automatic internal thermic cooling.

- For indoor and outdoor installation.

- Flame resistant, highest quality material, safe to grow edibles.

- Individual mounting on square rails to have control over wall ventilation and dryness of the mounting wall.

- Different modes: substrate variants to hydroponics utilizing the internal reservoir per module.

- Use different irrigation methods (recirculating, drain-to-waste) and liquid sources (roof, reservoir).

Please check our new 6 page info sheet with a much more detailed view of the components showing the installation options and metrics. If you are interested also in the component pricing, please send a request. Parts will be available in April/May 2021.

6. Shout-out to our existing users please add comments share production images.

Our user base is growing! That is fantastic to see. Also that some start using it in very creative ways.

Please add comments, share images and your experience and learnings using our components. We always like to see application images and they might also help others.

Please add comments, share images and your experience and learnings using our components. We always like to see application images and they might also help others.

- For active users here is our Facebook UserGroup for any practical solution or discussion of any issue. We will be systematically adding cases and solutions there.

- Leave us a Google-Review.

- Comment or share directly to a suitable post on our general facebook page if you think it could also be interesting for other users.

- Send them via email or ask for assistance on WhatsApp.

Any of those options are simple, quick and have tremendous value.

7. Looking for partners to share part of their booth with aponix as co-exhibitor.

We are looking for larger partners to share small part of their booth with aponix as co-exhibitor on trade shows in 2022. If that would be interesting for you as a representative of such a company, please get in touch with us. We did this in the past and it always was beneficial and fun to recommend each other’s range of products in a dynamic way, especially if the solutions complement each other.

8. US product partner EcoSprout with standalone setup and consumables.

If you are located in the US and you are interested in a complete standalone version of our vertical barrels, please say hello to our US product partner EcoSprout.

They also offer other useful soilless horticulture consumables like jute substrate plugs and mats, heavy duty 1020 trays and dry hydroponic nutrients.

9. What is an aponix vertical barrel / 3D-NFT

If you are new to the aponix vertical barrel, here is a quick summary of why aponix components exist:

The mission of aponix is to make hyperlocal edible plant production easy, productive and robust – for commercial operations running urban farms and for the advanced prosumer or hobby enthusiast. The aponix parts can be used to set up grow spaces for all these types of applications in very flexible and modular ways.

The idea is to pose an alternative to building racks or go super and still be able to use natural sunlight and reach plants with standard mechanical equipment like rail trolleys instead of using a scissor lift.

From April/May 2021 on there will also be an aponix living WallSystem.

Remember: Height = number of grow spaces = always variable.

Plant spacing and plant shape = configurable.

No fixed or blocking elements (tables or racks) needed.

Highest quality materials possible, made in Germany.

Exciting product partnership scheme. You want to know more about this? Please visit our product partner page for more details and conditions

Check out these aspects: Decision Process Vertical Barrel Configuration | Integration Examples | Key Features and Metrics | FAQ | Product Partners | Bundles